The duration of Brighetti tools depends on the conditions of use, more or less correct, on the characteristics of the material to be machined and on the amount of material removed according to the section to be made.

Tips to ensure a longer life of the broach

1) Use a machine tool stiff enough to withstand strong axial thrusts which may cause vibrations and / or bending.

2) A longer life is obtained by checking, at regular intervals, the cutting edge of the tool and possibly intervening with light front re-grinding before the edges become excessively worn.

Re-grinding can be done flat (zero rake angle).

By re-grinding the tool, the profile size is progressively reduced, approximately 0.01 for every tenth of mm removed.

On the contrary, dies for external profiles have the cutting section which increases progressively.

Since it is necessary to keep the cutting axis concentric to the axis of the work-piece, the protrusion of the tool from the support surface of the broaching head shall constantly remain:

– 45 mm for il G16L

– 25 mm for G12 e G16

– 18mm for il G8

– 10 mm for il G5

If the re-grinding exceeds 1 mm, it will be necessary to compensate with a ground washer to be mounted on the tool shank to restore such measure.

TYPES OF GRINDING UPON REQUEST ACCORDING TO THE TYPE OF MATERIAL TO BE MACHINED

> “Brighetti Meccanica” STANDARD GRINDING

Grinding with flat surface and 2° rake angle.

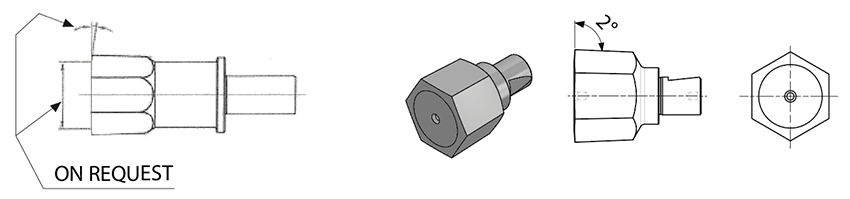

> CUP GRINDING

Grinding upon request for non-ferrous materials and stainless steel with Rm less than 900 n / mm2 2° rake angle.

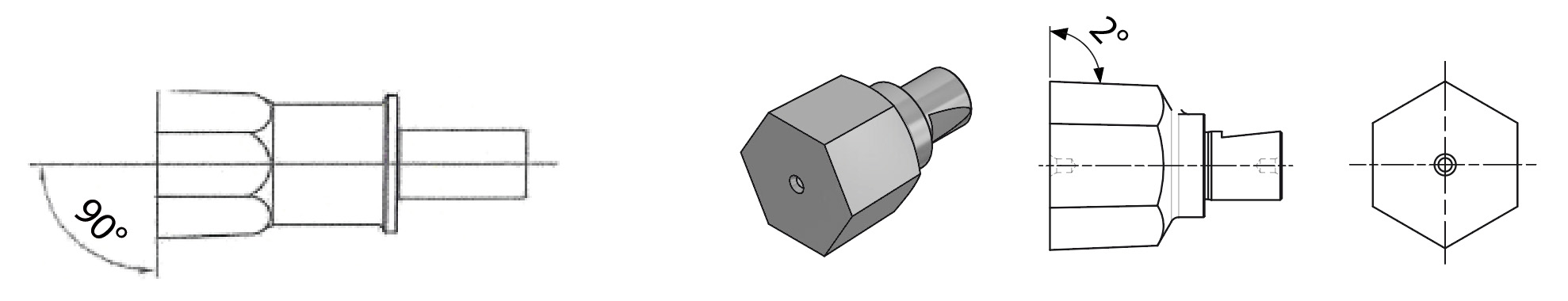

> FLAT GRINDING PERPENDICULAR TO THE EDGE

Grinding upon request for cast iron and stainless steels with Rm higher than 900 n / mm2 2 ° rake angle.