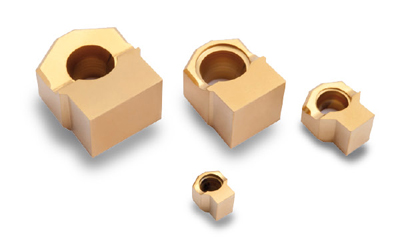

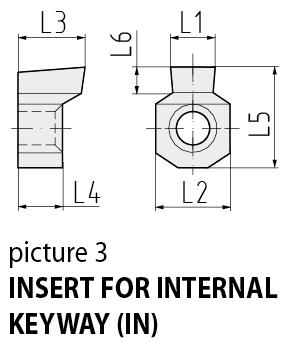

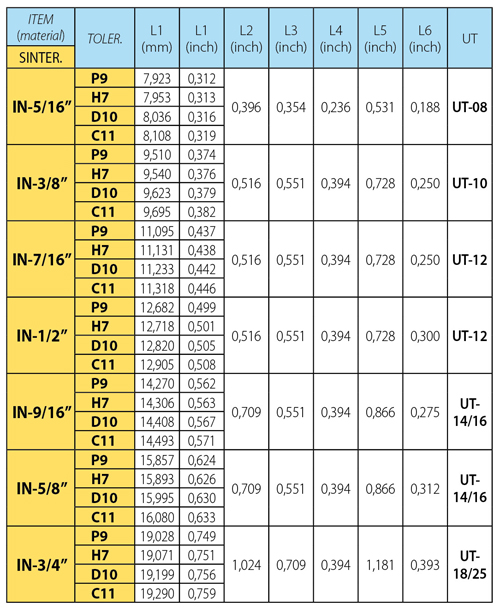

Inserts are made in sintered steel with a TiN coating. The material and the coating give to the insert a great hardness and let it bear in the best way possible the great number of hits that are typical of this kind of machining. It’s important to point out that for some inserts (in particular inserts with P9 and H7 tolerances), a 0,2×45° chamfer can be realized.

This chamfer prevents the flash from forming during the machining of the keyseat.

Inserts can be re-grinded twice or three times. This feature reduces production costs.

All insert sizes indicated in picture 1 are always available in stock.

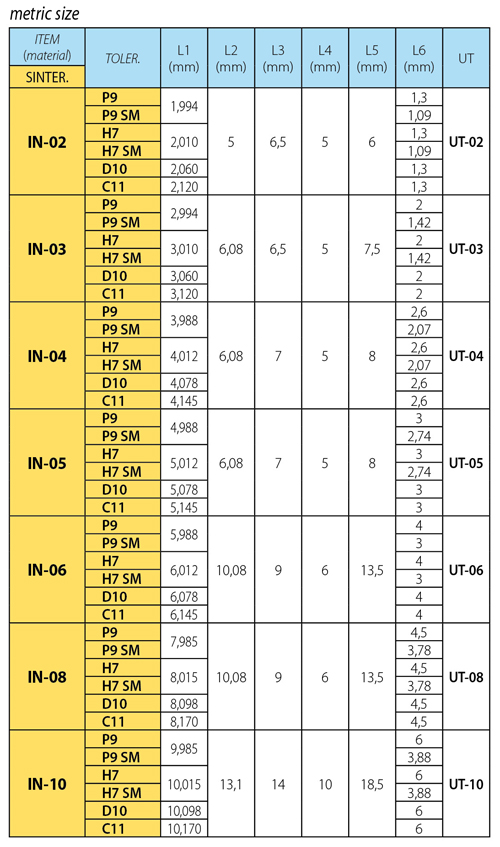

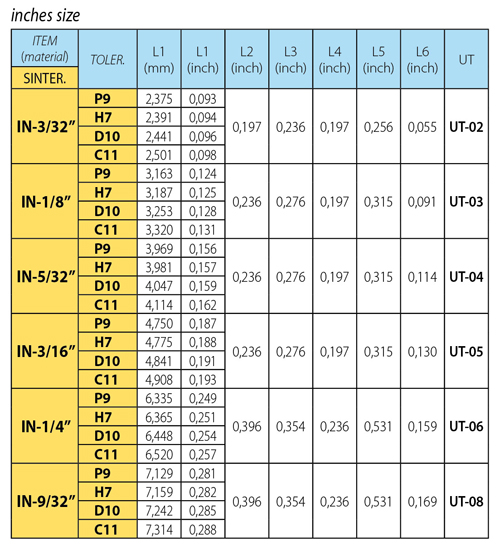

Inserts are produced with metric and inches sizes.

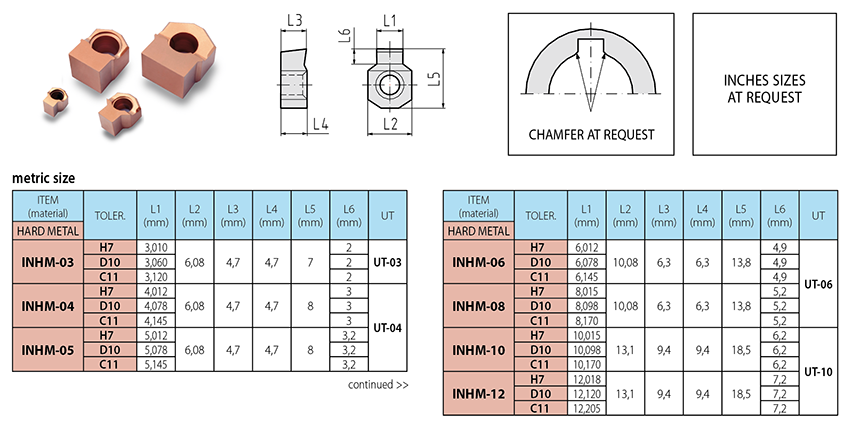

* In the intersection between the hole and the wall of the keyseat, for every insert sizes (IN3, IN4, IN5, etc…) with P6 and H7 tolerances it is possible to request a 0,2×45° chamfer, in order to prevent the flash from forming.