When machining square holes, it is advisable to remember that the amount of material to be removed is almost twice as high as in a hexagonal hole, therefore the thrust to be applied is greater.

These types of machining normally require very rigid and high-power machines.

If it is possible, especially beyond 20mm square, some precautions should be adopted:

1) the pre-hole must always be as large as possible

2) when possible, it is advisable to request that the edges are rounded off in order to remove the sharp edge which is the most fragile point of the tool (see “TYPES OF GRINDING UPON REQUEST THAT PROTECT THE BROACHES FROM WEAR”)

3) if the square section is required with four complete planes, a UT-SQ tool can be used for slotting.

Of course, the same considerations apply to the execution of large hexagonal holes, usually exceeding 26 mm.

TYPES OF GRINDING UPON REQUEST THAT PROTECT THE BROACHES FROM WEAR

To avoid or remedy the possible breaking / chipping of the edges due to the resistance of material, the tools can be ground as shown below:

> EDGES WITH RADIUS

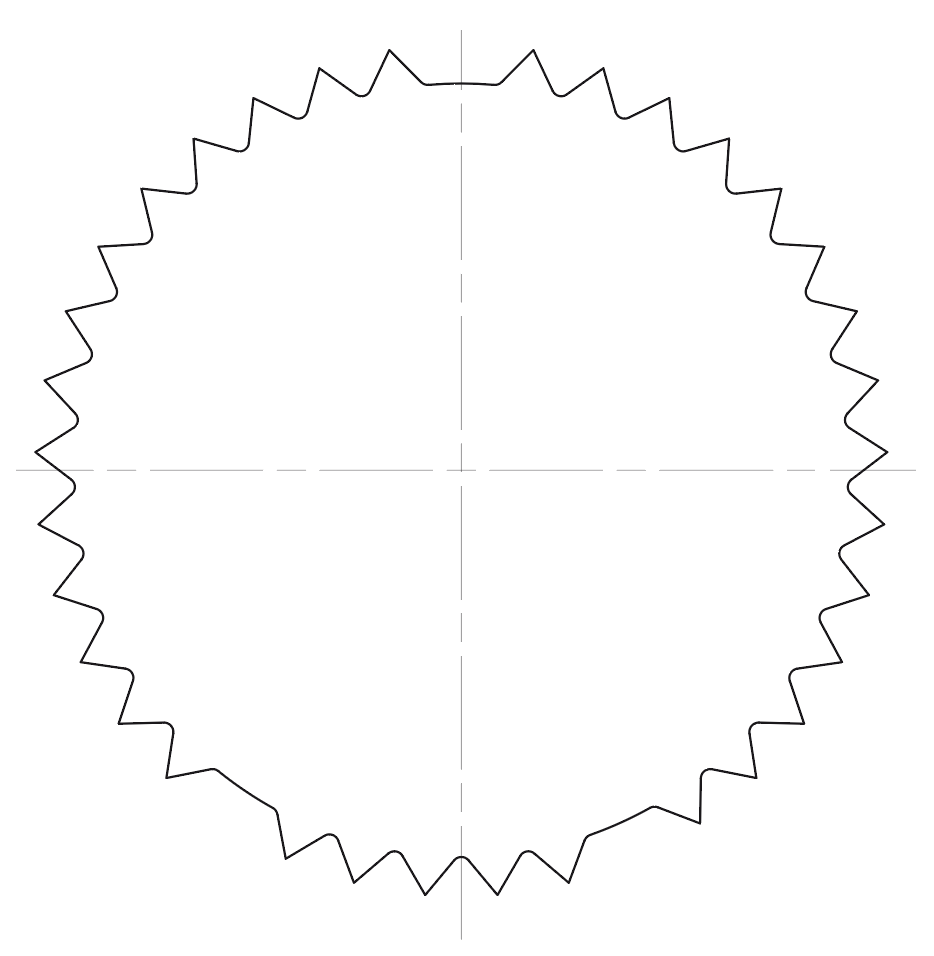

square / hexagonal profile

Square broach with RADIATED EDGES

> EDGES WITH RECTIFIED DIAMETER

square / hexagonal profile

Square broach with RECTIFIED EDGES

> CHAMFERED EDGES

square / hexagonal profile

Square broach with CHAMFERED EDGES

SPECIAL PROFILE PROCESSING

1 – EVOLVENT TOOTHING (ex. DIN 5480):

2 – MISSING TEETH: