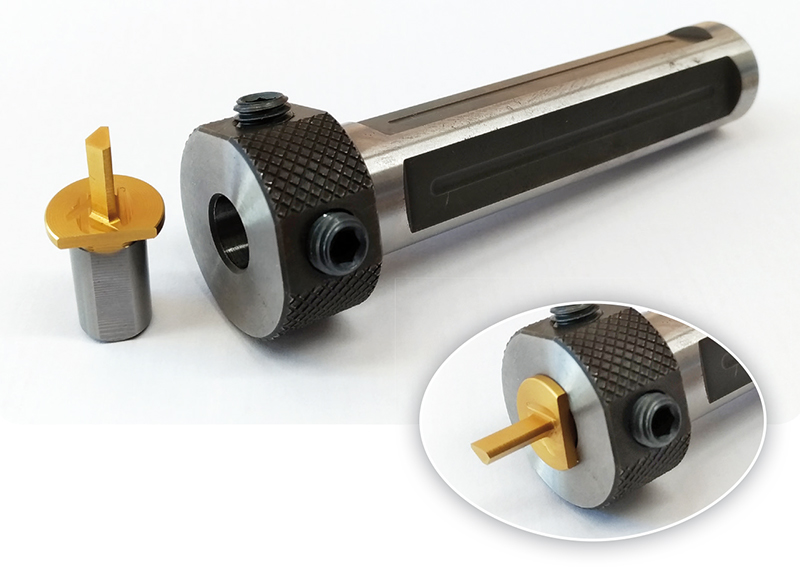

Brighetti Meccanica, to accommodate the need for machining increasingly smaller components, developed the MINITOOL line.

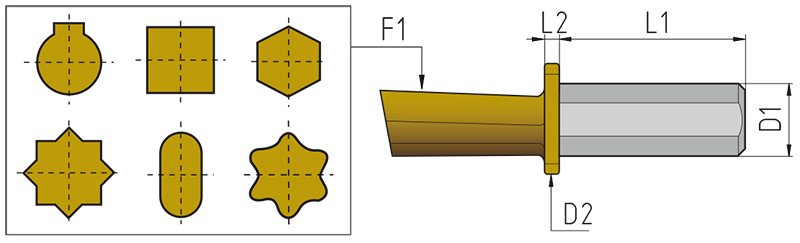

This line envisages the use of integral inserts that allow extremely small cut profiles to be obtained, with the most diverse geometries.

In order to ensure a high rigidity of the tools and to obtain absolutely perfect tools for the desired operation, the integral inserts are created according to client requests, taking into account all specific needs.

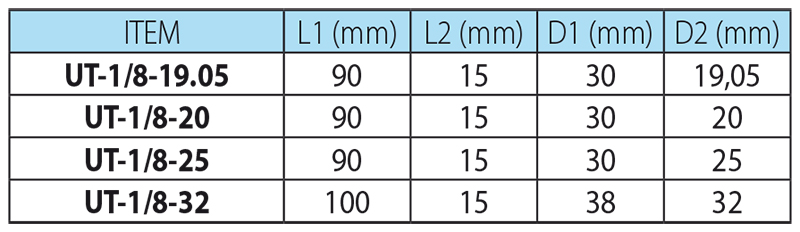

The MINITOOL series inserts can be housed in the relative insert holder UT-1/8-25 or, as an alternative, in insert holder UT-1/8-32. The above insert holders, in turn, can be mounted inside eccentric bushes and, in this way, eventual errors in the symmetry on CNC lathes that do not have a Y axis, can be corrected.

On the other hand, MINITOOL inserts can be blocked in the machine’s tool holder with a simple mounting clamp (e.g. an ER plier). In this case, it is preferable for the machine tool to be equipped with a Y axis.

The INSERT HOLDER tool of the MINITOOL line is constructed in a way that allows the integral insert to be mounted swiftly and to be housed with extreme precision.

It is available in two versions: with 25 mm and 32 mm diameter fastenings.

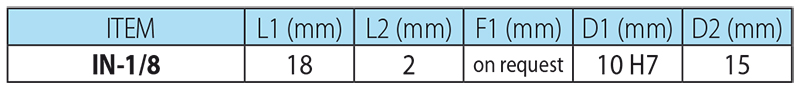

The INTEGRAL INSERTS of the MINITOOL line present a flat part on the 15 mm diameter collar, which allows the operator to control the correct position of the insert very swiftly by using a common dial gauge or feeler. These can be made in two alloys: sintered steel or high tenacity carbide.

The inserts have a very lengthy duration and can be re-ground frequently before having to be replaced.

The type of grinding and coating must be assessed by considering the type of material to be processed. Integral inserts can be housed in insert holder UT-1/8-25 or UT-1/8-32.